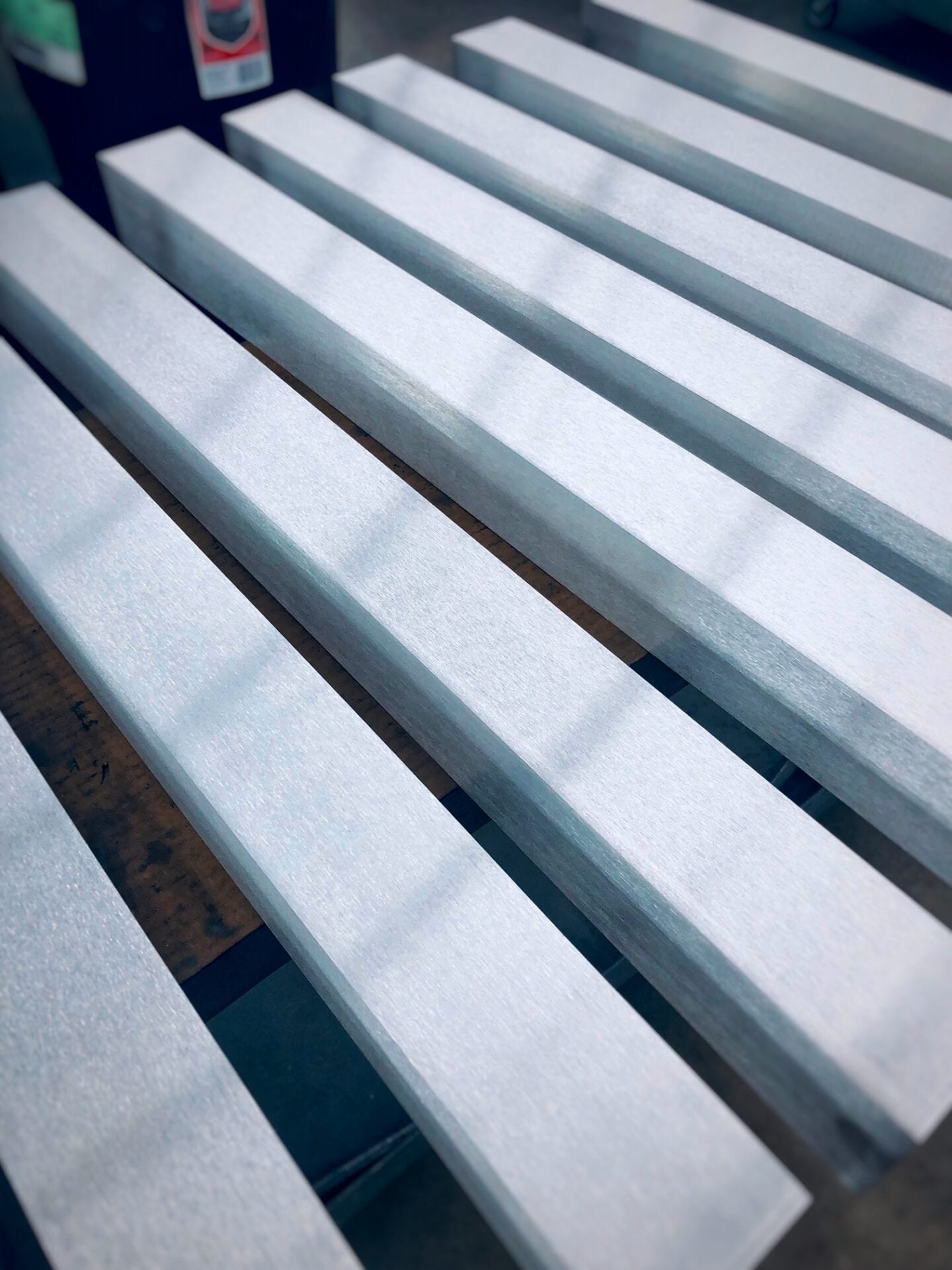

A line grain finish is a scratch or sanded, linear pattern, used to remove or minimize scratches, material defects, mill scale and porosity. Then a pass to leave a uniform finish. Buds Polishing has the ability to apply satin finishes, brush finishes, and/or line grain finishes, on various metals and even plastics! We can achieve these brush finishes or line grain finishes by our 9′ sand stroker, 2 time savers (25″ AND 52″), our semi-automatic tube-spinner, and even manually by hand. These finishes are suitable for jobs large or small; custom or production.

Grits used can be anywhere from 36 grit up to, but not limited to, 600 grit. Though, 80-220 grits are most commonly used. Abrasives used range from line graining finishing aluminum oxide, zirconia, scotch bright/non-woven, and silicon carbide. Line graining is usually used on and best suited for flat/sheet type shapes. However; line grain, satin or brushed finishes can also be applied to castings, billet/machined, and small or large parts.

These finishes are great for hardware, fabricated parts, aerospace components, automotive pieces, food processing or sanitary surfaces, appliances, handrails and elevators. Line graining on a cylindrical, tube or round pieces can be achieved with the grit lines going in annual/short direction, longitudinal or long direction; in the inner and outer diameter as well. See our Tube Page Please ask for details on specific sizes or shapes.

Buds Polishing can also touch up and blend items that have been welded to hide effects of weld discoloration, and blend direction of grain lines. We can also show grain lines in a “miter” to showcase designs on corners or 90 degree angles.

Special note how to: most items that are to be welded or fabricated should be polished or line grained BEFORE fabrication, then touched up after. This usually cuts cost, improves quality of finished product.

Also, a line grain, satin, or brush finish is usually 1/2 the cost of a bright or mirror finish if you are on a budget.

List of the Unique Metal Line Grain Finishes offered at Buds Polishing for metal sheet, plate, and flat bar:

#3 Finish-Rough Metal Grinding

Also known as grinding, roughing or rough grinding. These finishes are coarse in nature and usually are a preliminary finish applied before manufacturing. An example would be grinding gates off of castings, deburring or removing excess weld material. It is coarse in appearance and applied by using 36–100 grit abrasive.

When the finish is specified as #3, the material is polished to a uniform 60–80 grit.

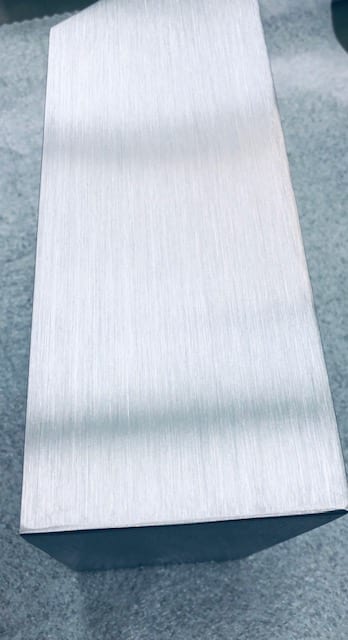

#4 Architectural Finish-Brush Metal Finishing

Also known as brushed, directional or satin finish. A #4 architectural finish is characterized by fine polishing grit lines that are uniform and directional in appearance. It is produced by polishing the metal with a 120–180 grit belt or wheel finish and then softened with an 80–120 grit greaseless compound or a medium non woven abrasive belt or pad.

#4 or #5 Dairy or Sanitary Finish

This finish is commonly used for the medical and food industry and almost exclusively used on stainless steel. This finish is much finer than a #4 architectural finish. One takes great care to remove any surface defects in the metal, like pits, that could allow bacteria to grow. A #4 dairy or sanitary finish is produced by polishing with a 180–240 grit belt or wheel finish softened with 120–240 grit greaseless compound or a fine non woven abrasive belt or pad.

#6 Finish-Satin Metal Finishing

Also known as a fine satin finish. This finish is produced by polishing with a 220–280 grit belt or wheel softened with a 220–230 greaseless compound or very fine non woven abrasive belt or pad. Polishing lines will be soft and less reflective than a #4 architectural finish.

Please contact Buds Polishing for a free quote for you line graining, metal brushing or satin finishing requirements today!